Chamfering and bending is a common method used in plastic thermoforming. As an expert in plastics processing, we use efficient chamfering machines to produce high-quality, functional models and components for our customers in the machine building, automotive and medical industries. Our specially designed equipment enables us to precisely chamfer and easily bend the material. With more than 30 years of experience, the family-run business Kirsch Kunststofftechnik produces models and components of excellent quality and in compliance with DIN EN ISO 9001:2015. Rely on our expertise in chamfering and bending for your product

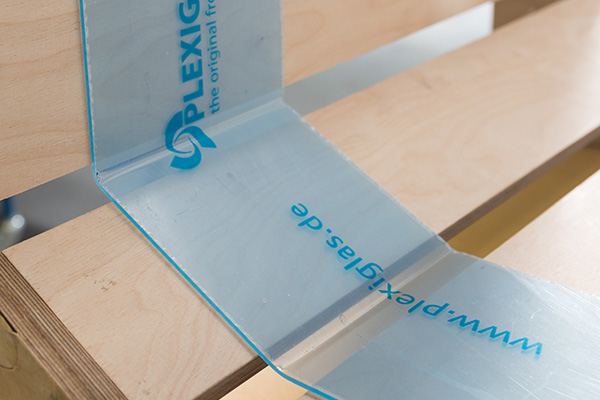

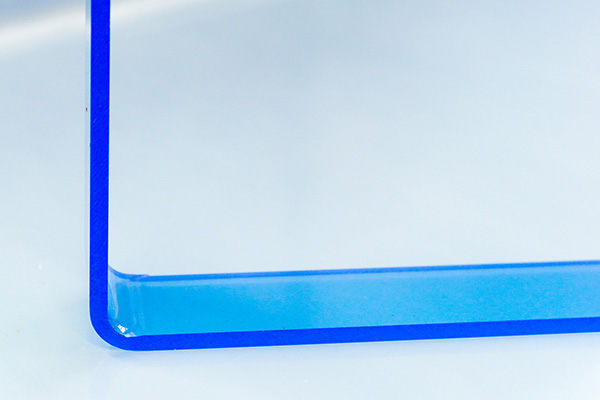

Chamfering is a process in which the sheet material is linearly reshaped using a special chamfering tool. The material is heated linearly in certain areas in order to bend it. The workpiece is then fixed in a special device so that it retains the desired shape when the part is cooled. Sheets made from polycarbonate or PLEXIGLAS® are particularly suitable for this process. We use powerful quartz glass heaters to heat both sides of the material which results in short cycle times. Chamfering is performed with precision and accuracy using a bending edge or a bending template.

As an expert in plastic thermoforming, we manufacture models and components that are tailored to customer-specific requirements. We support our customers throughout the entire process, from the initial draft to the finished component and logistics. The powerful technology of our modern folding machines enables us to create 4 bends per work process on a working length of up to 2000 mm. We realise our customers’ ideas and visions using top-quality materials, state-of-the-art technology and innovative solutions. Professional, effective and customer-focussed.