Thermal forming of plastics is one of the most important areas of plastics processing. As a specialist with over 35 years of experience, Kirsch Kunststofftechnik provides forming services to the highest standard and with outstanding visual quality. We use state-of-the-art machinery to precisely and reliably meet our customers’ individual requirements. Rely on us as a plastics processing specialist and find tailored solutions for your ideas and projects.

The special thermoplastic properties of plastic facilitate the creation of various designs. With five different thermoforming ovens, Kirsch Kunststofftechnik is able to process sheets and components of up to 3500 x 2500 mm, offering plenty of creative freedom for your individual products. We work using special filter technology that enables transparent panes to be precisely treated without any dust inclusions.

In order to offer our customers a wide selection of materials, our ovens feature advanced control systems that enable the necessary heating and cooling curve to be achieved for each plastic in a targeted manner. Thanks to accurate temperature regulation, the cooling phase can be precisely controlled so that the plastic cools with minimal distortion to produce top-quality results.

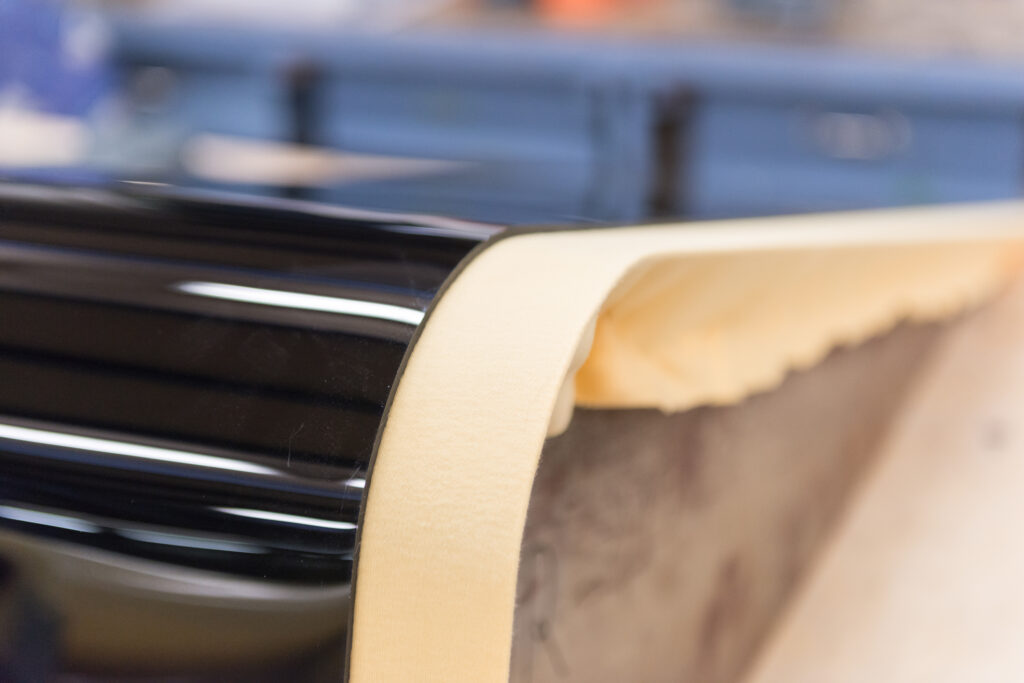

Due to their high resistance and durability, our thermoformed products can be used for various purposes such as vehicle panes, components or machinery protection.

As an expert in plastic thermoforming, Kirsch Kunststofftechnik manufactures products tailored to your requirements and expectations. We offer innovative solutions to support our customers from the initial concept to the finished product. We realise your projects both in two-dimensional and three-dimensional format. Our wide range of high-quality plastics enable us to meet specific customer requirements. Are you planning a new product? No problem! We’ll find the right solution based on your drafts and plans.